A valve through which the fluid passes in one direction and backflow of fluid is avoided. The valve acts only under the pressure of fluid having no controller device on outer body. Fluid circulation is controlled by a disc which gets away from valve body when fluid pressures and returned to its previous position when pressure stops.

Swing check valves are designed and manufactured according to the

Iranian National standard No. 3664 and is made of hot forged brass. The main form of ribs is calculated

in inches based on EN ISO-228 Standards. Swing check valves are used usually in urban water supply, thermal installations of buildings, industrial purposes, pumps, petroleum and oil networks and generally in all networks in which the fluid flows only in one direction. Followings are benefits and advantages of this product:

- Resistance against corrosion and tear

- Resistance against sediments

- Full sealing

- Silent on-off position

Advantages

Mounting a sealing rubber washer of NBR Material on the steel disk (lid) will completely seal the waterway zone at the same time preventing the noises produced by impact of the disk against the valve body during on-off operations.

Technical Specifications

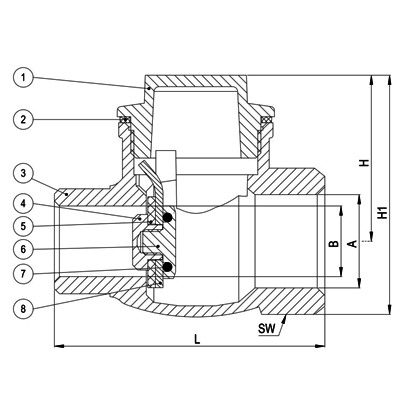

| Order No. | Size (inch) | A (inch) | B (mm) | L (mm) | H (mm) | H1 (mm) | SW (mm) | Operating Temperature (C) | Working Pressure (bar) |

|---|---|---|---|---|---|---|---|---|---|

| 5060 | G1/2 | 1/2" | 13 | 54 | 31 | 45 | 26 | 170 | 16 |

Analysis of Materials

Body and all parts of Wafer swing check valves manufactured by this Company are according to the last standards, the analysis of which is according to the following table

| No. | Name of pieces | material |

|---|---|---|

| 1 | cap | MS58 Hot Forged brass |

| 2 | sealing washer | Hostaform plastic |

| 3 | Body | MS 58 Hot Forged brass |

| 4 | valve nut | MS 58 brass |

| 5 | sealing rubber | NBR rubber |

| 6 | valve pin | MS 58 brass |

| 7 | O-Ring | NBR rubber |

| 8 | valve | SS 304 stainless |